vacuum-formed trays

vacuum-formed trays

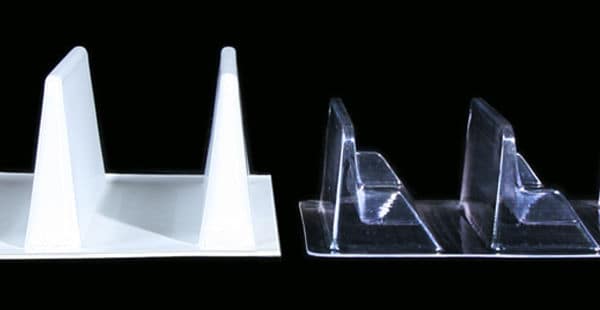

Popco offers design and mold engineering for trays with custom-height fins and varied numbers of fins. Following design and production of your mold, we then run the tray. For a custom run, the minimum number of trays is 500. Runs of 1000 or more will produce the best per-tray price.

Mold development costs vary depending on the complexity of a tray. On the low end, a mold may cost roughly $1000.00. For a complex tray, mold costs can exceed $5000.00. Each custom project will be quoted to find the best balance between cost and tray design.

For more information on custom vacuum-formed trays, please contact Popco to discuss your project and initiate a quote.

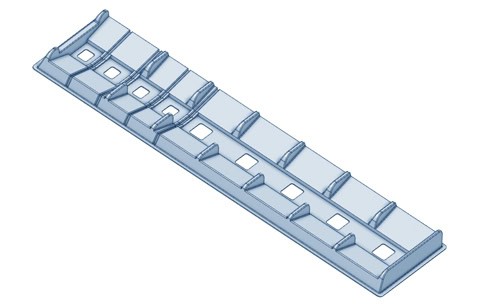

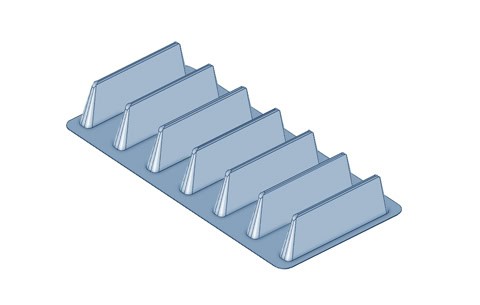

pizza tray

- 7″ wide / 1.30″ high / 24″ deep

- 0.025 HIPS (High-Impact Polystyrene)

- 7 cavity – modifiable to 5 or 6 cavity

- segmented back cavities can be shortened to fit various cooler depths

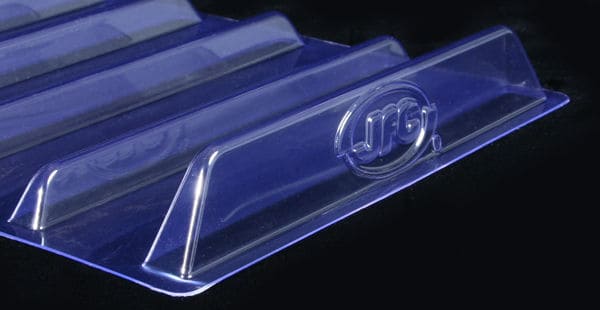

clamshell tray

- 7.5″ wide / 2″ high / 18″ deep

- variable

- 6 cavities

- 2″cavity depth / two drainage holes per cavity

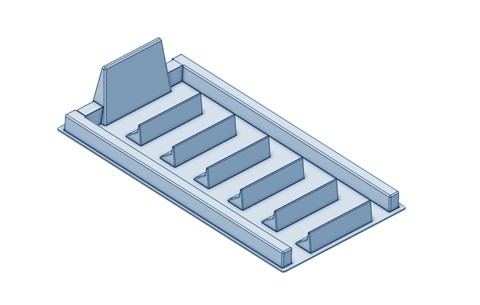

6-row filter tray

- 5.18″ wide / 2″ high / 13.88″ deep

- 0.060 HIPS (High-Impact Polystyrene)

- 6 cavity

- 1.42″cavity depth / 0.50″ radius corners on base

shrimp tray

- 7.5″ wide / 2″ high / 14.18″ deep

- 0.040 PVC (Polyvinyl Chloride)

- 6 cavity

- 1.65″cavity depth / (2) 0.50″ diameter drain holes per cavity

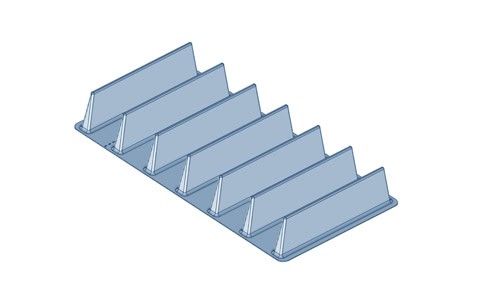

meat tray

- 7″ wide / 3.51″ high / 13.53″ deep

- 0.060 HIPS (High-Impact Polystyrene)

- 6 cavity

- 2.55″ back fin supports packages / 0.96″ front fin reveals package graphics

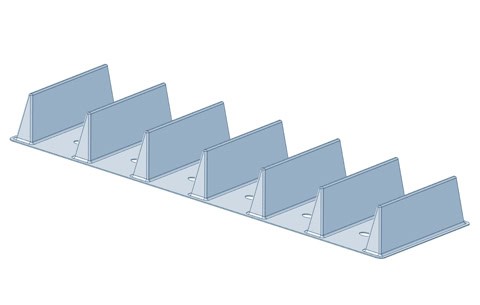

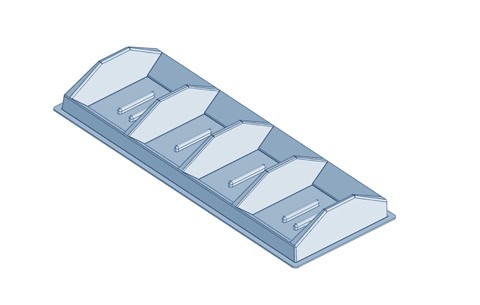

4-row angled rib tray

- 5.5″ wide / 1.65″ high / 14″ deep

- variable

- 4 cavity

- 2.80″cavity depth / chamfered fins

contact us

"*" indicates required fields