Corrugated material is widely used in merchandising constructions such as floor standing displays and dump bins. The strengths of corrugated materials are many: cost-effectiveness, printable with your graphics, flat shipping, and substantiality to name a few. When a corrugated display needs to be strong as an ox, assembly parts such as Popco’s corrugated shelf-support clip become essential.

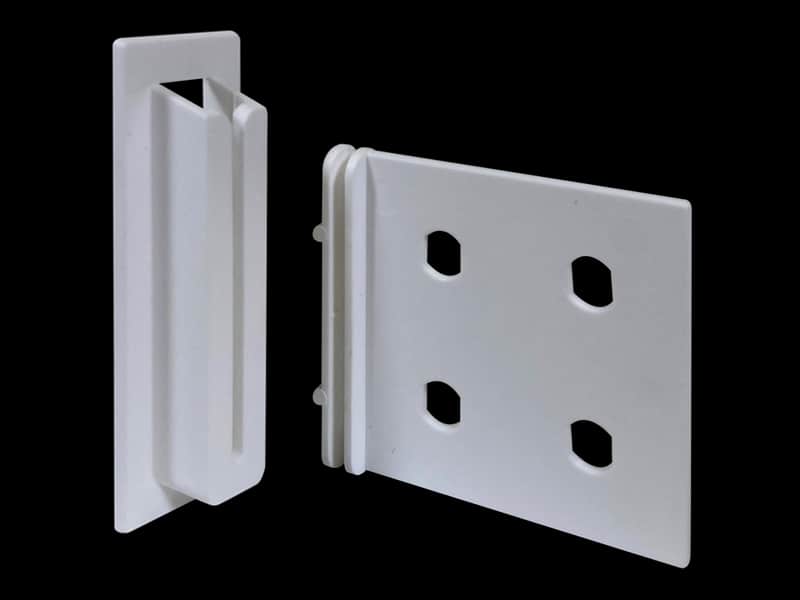

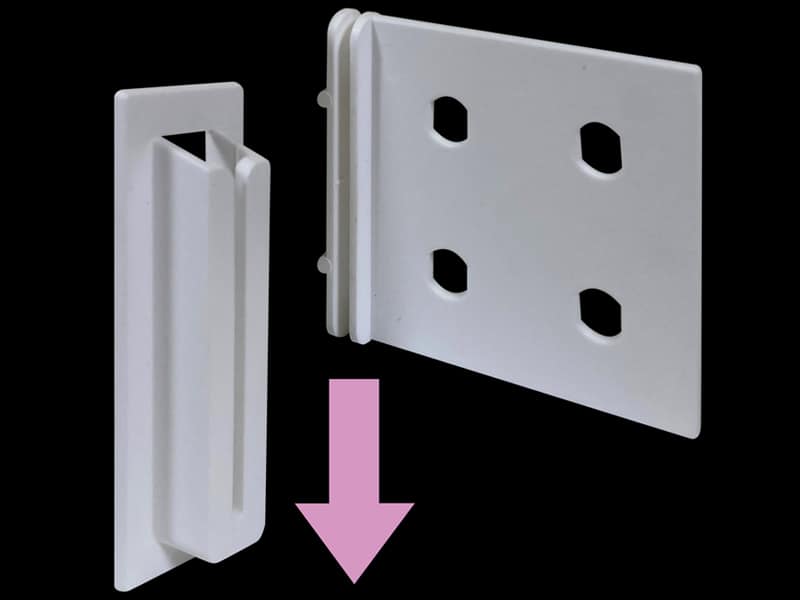

Popco’s corrugated shelf-support clip system includes two pieces that work together to create a means of supporting shelves on displays. The back piece, shown above on the left, is placed on the back of a corrugated display and protrudes through a die-cut opening on the display.

The front piece, shown above on the right, is inserted into corrugated material, and glued in place, creating an extra-strong support structure for a shelf. It then slides into the corresponding slot on the back piece, connecting the shelf to the back of the display.

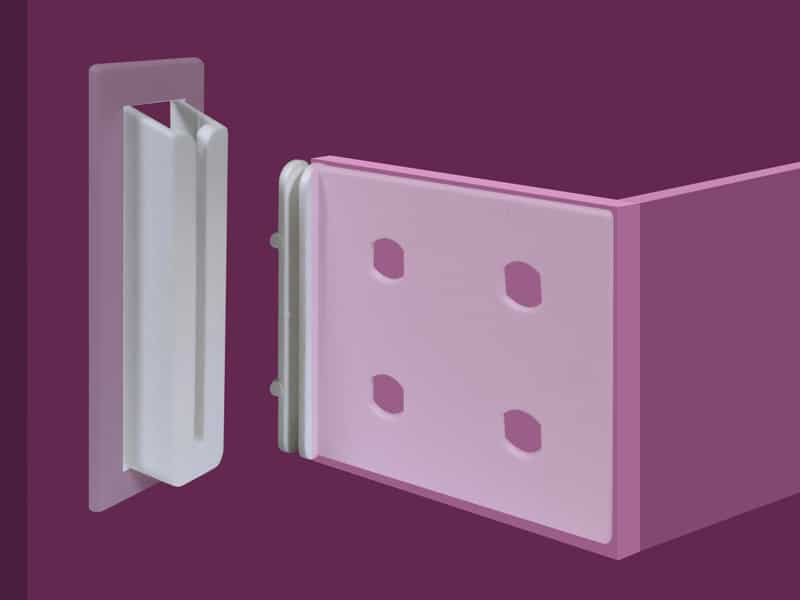

The illustration above shows how the back piece of the corrugated shelf-support clip system protrudes through a die-cut opening on the display, and how the front piece is inserted into the sides of a shelf. Inserting glue along with the front piece fuses the shelf-support clip to the corrugated material. The four holes in the clip help the glue form and extra-secure bond.

When complete, the shelf can support significant weight and often, displays assembled with these parts support bottles in liquor stores. In addition to the strength of the display, a display constructed in this manner can ship flat and can be quickly and easily assembled in the field. As we said, simple, strong and meant to last… support, Popco style.