for visibility and accessibility

In grocery store coolers and freezers, and on store shelves, product pushers are an ideal tool for merchandising packaged goods. With product pushers, packages are kept front and center, visible and accessible to customers.

Once assembled, they are perfect merchandising tools, but challenges exist on the front end when choosing product pushers. The details of a package, and the specifics of the space in which the product pusher will be used, must be known so that the right combination of components is assembled. Bespoke construction is essential — one size most definitely does not fit all.

first things first

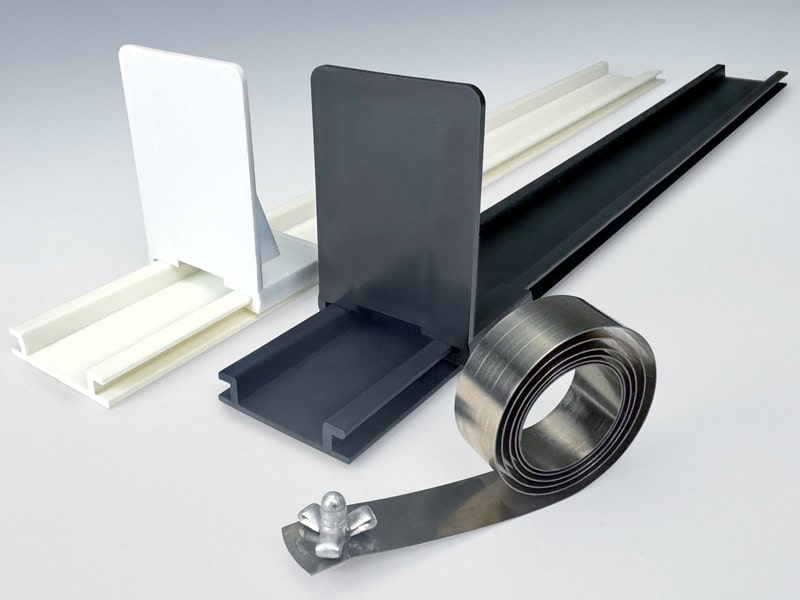

The first component that Popco offers for a product-pusher assembly is the pusher “ram”, shown here. Our rams are injection molded from either polypropylene (for use in coolers or on store shelves), or nylon (for use in freezers). Standard rams are offered in white and black. For large quantities, custom colors are available.

the rails come next

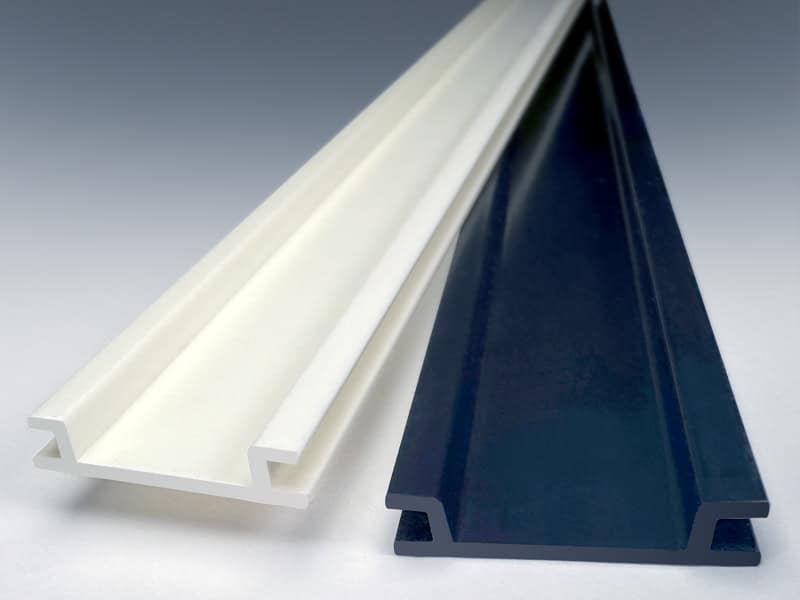

The next component of a product-pusher assembly is the track, or “rail”. Channels on the left and right sides of the rails correspond with channels on the bottom of the rams. When the channels are combined, a ram will slide easily back and forth on a rail.

Rails are extruded in lengths that correspond to cooler or freezer depths, or the depth of a store shelf. They are typically made from PVC or ABS plastic and their standard colors are also white and black (with custom colors available for large quantities).

spring into action

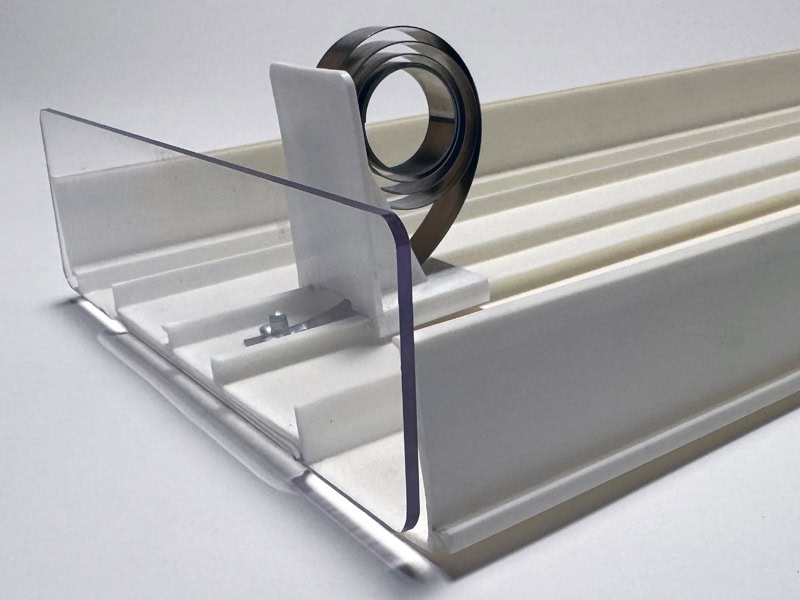

Rams and rails are affixed to each other with a spring. This is a critical phase in the product-pusher assembly. The springs must be matched to the package’s size and weight. To do this properly, Popco works closely with customers and the spring manufacturer.

Ideally, a sample of the package can be provided so that the spring has the perfect amount of pressure — enough to move multiple packages forward along the rail, but not so much that there’s a risk of denting or crushing the packages.

about face

The last piece of the puzzle is the product-pusher’s front face. For this, Popco provides a heat-bent piece that attaches to the bottom of the rail, using the same rivet that holds the spring and ram in place. When adding this finishing touch to a product-pusher assembly, Popco works with our customers to determine height of the front face and other design particulars such as color or branding.

If you’re looking for product pushers, you’ve come to the right place. Reach out to Popco to get your project started.